New CNC Machining Centre for apt Extrusions B.V.

The apt Group continues to invest in state-of-the-art technology and adds a machining centre to its production plant in Roermond (NL). In this way, aluminium profiles can be further processed by milling, drilling and sawing them to customer specifications on site.

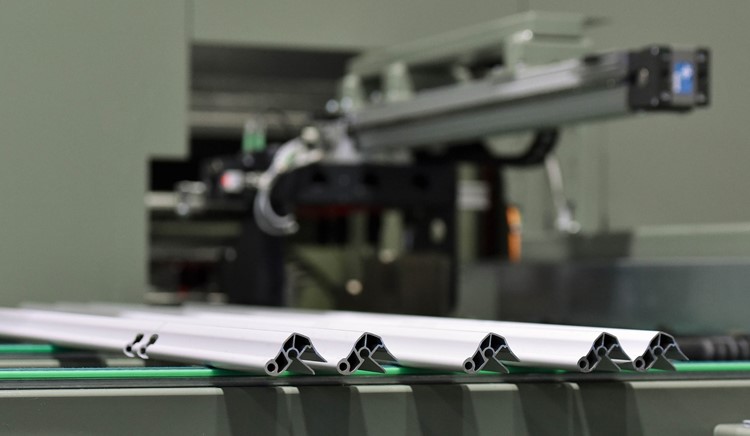

At the beginning of 2020, apt Extrusions B.V. put a new Computer Numerical Control (CNC) fabrication centre into operation in Roermond, the Netherlands. On-site extruded aluminium profiles – either mill finished or in an anodized version – are further processed according to customer specifications by computer-controlled programs in a consistent, reproducible quality.

First of all, profiles with a maximum cross-section of 200 x 150 mm pass the milling unit behind the automatic feeder. It consists of four milling motors, which are mounted on a turntable and can rotate around an axis of 360°. The motors are controlled separately so that they can mill out any desired shape independently of each other. If necessary, they can also drill holes and special threaded holes. Behind the milling unit there is a saw module that cuts the profiles to the desired length. A variable cut angle between 45° negative up to 45° positive can be achieved. “The finished profile can have a length of up to four meters,” says Alex Verbeek, Process Engineer apt Extrusions B.V. “An extension to up to five meters is possible upon customer request.” The finished profiles are automatically transferred to the unloading table. After a quality control the profiles can then be prepared for logistics.

“We have successfully expanded our customer offering by investing in the machining centre,” reports Astrid Kurvers, Sales Manager apt Extrusions B.V. “The clear advantage is that our customers now receive their finished aluminium product from a single source – we transport the profile directly from our extrusion press or anodising line to the machining centre. This leads to shorter delivery times, a contact person for the customer and a quality control for the final aluminium component”.

apt Extrusions B.V. celebrated its 50th anniversary last year. Since its foundation, the company continually developed. Most recently, investments were made at the site in its fabrication competence. In 2017, a modern MPS saw was acquired and in 2018 a spindle saw was purchased to supplement the existing sawing systems. Those are characterised by achieving very tight production tolerances.