Advice and support

We advise you from as early as the product development stage, and work together with you to draft the best possible outcome. Here, we can support you from the first idea, to developing the best possible solutions for complex tasks, right up to efficient production.

Specialised know-how

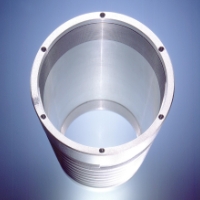

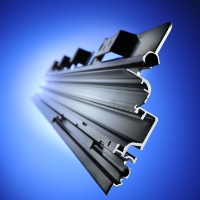

Our focus is on the construction, transport, automotive and industry markets. Here, we can incorporate our special knowledge into your project and develop independent and co-engineered solutions, from the ideal profile geometry right up to the complete aluminium component systems. In this way, for example, we have developed various aluminium hatches for buses, which reduces their overall weight and allows transport companies an additional load. Here, aluminium sheet metal as well as extruded profiles are used.

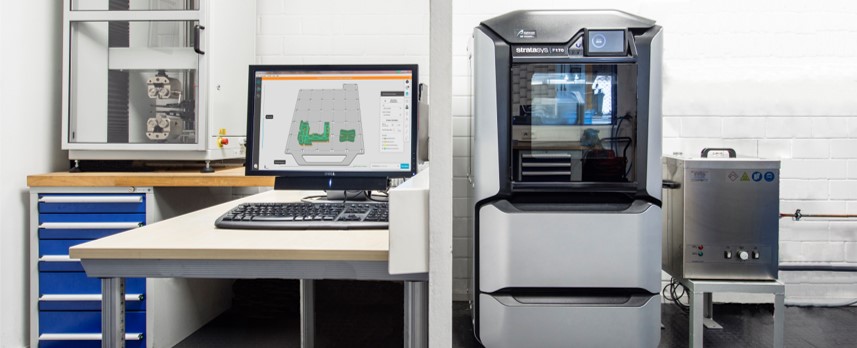

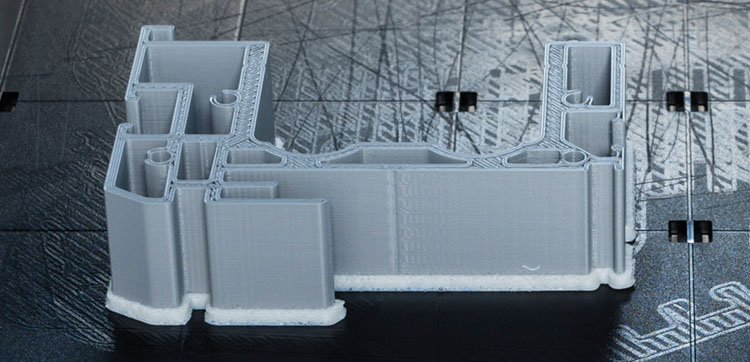

CAD construction

The ideas and designs can take shape using the latest Computer Aided Design (CAD) technologies in the shortest time. We use the following software for this: