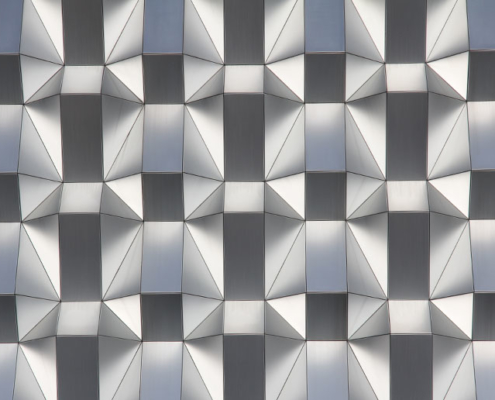

Core competence aluminium

Our passion for more than 50 years

Universal metal discovered at a late stage

The element aluminium was first discovered in 1825 by the Dane Hans Christian Oersted (1777 – 1851) during the analysis and decomposition of alum earth. Pure aluminium was produced by Friedrich Woehler (1800 – 1882) in 1827 by reducing aluminium chloride with potassium. Only much later, in 1854, Parisian chemist Henri Sainte-Claire Deville (1818 – 1881) succeeded in synthesising pure aluminium out of the mineral cryolite through a reduction with sodium. However, the process required a great deal of energy and was therefore not suitable for mass production.

Large-scale production since 1886

In 1886, Paul Louis Héroult in France and Charles M. Hall in the USA first discovered the fused-salt electrolysis of aluminium at almost the same time and independently from one another – Today, this process is known as the Hall-Héroult process. This paved the way for large-scale production of this very important metal. Aluminium is one of the most important materials for today’s industry – its possibilities of use are practically unlimited.