Latest Technologies

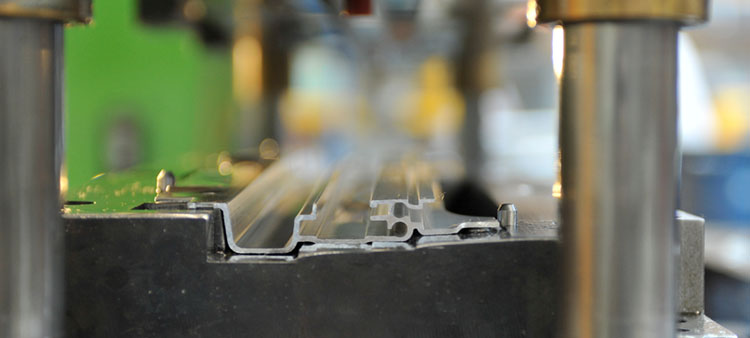

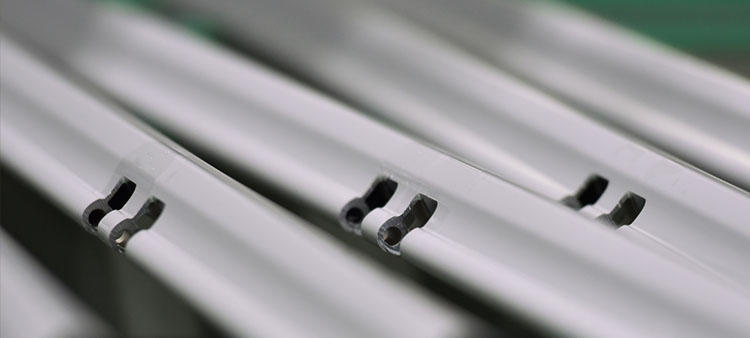

For accurate aluminium processing

Are you looking for a partner for aluminium processing? We have the necessary know-how, state-of-the-art machinery and several years of experience to provide you with the kind of aluminium you want. In the area of aluminium processing, we focus on the mechanical processing of aluminium profiles and sheet aluminium. On our machines, for instance, we are able to process aluminium profiles up to a length of 14.5 metres.

For special components or assembly groups, our apt Products division is available to you. We accompany you from the development phase. You can also find further information on our information page about our aluminum fabrication competencies.

State-of-the-art Technologies

- Sustainable aluminium processing

- Wide variety of processing options

- Prototypes, small and large series

- Full adherence to deadlines

- Short response, set-up and throuput times

- One-stop shop

- Certified processes