Precise aluminium machining

With many years of experience & state-of-the-art machines

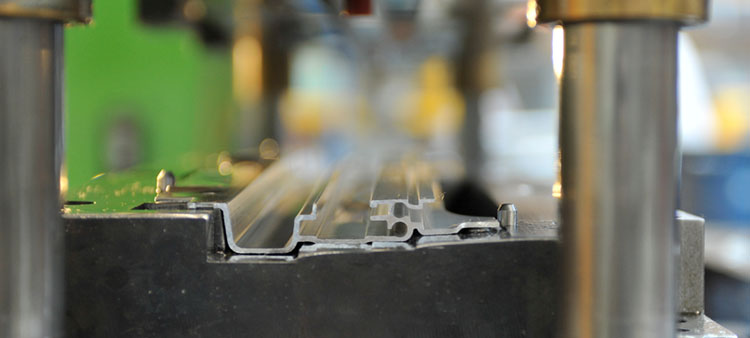

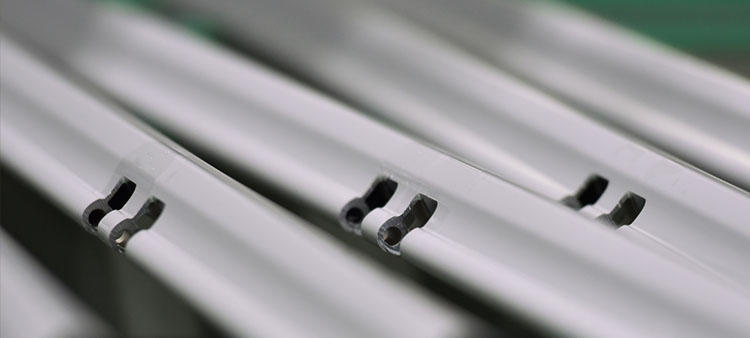

From the aluminium profile to the finished workpiece, apt is your competent partner for the processing and finishing of aluminium. To achieve this, we combine experience and technical expertise with state-of-the-art processes.

In order to optimise response and delivery times, we also carry out the further processing of customised aluminium profiles for our customers. Here too, we have state-of-the-art processes for forming and shaping, sawing and cutting, CNC turning and milling and so on. We can realise both small and large series at attractive prices and with absolute adherence to deadlines. Approximately 20,000 tonnes of aluminium pass through our processing department every year.

Strengths in our aluminium machining centre

- Professional and competent advice

- Consistent quality

- Everything from a single source

- A wide range of processing options

- Prototypes

- Small and large series

- Short response, set-up and throughput times

- One-stop shop

- Certified processes